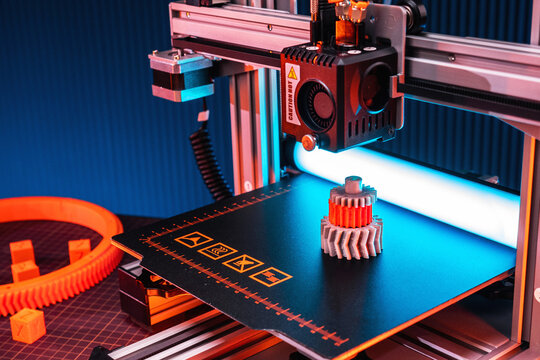

The aerospace industry is known for its high standards of precision, safety, and innovation. With the growing demand for lighter, stronger, and more complex components, traditional manufacturing methods sometimes fall short of meeting these needs efficiently. Commercial 3D printing services have emerged as a transformative solution, enabling the aerospace industry to achieve new levels of performance and efficiency. This article explores how 3d printing services is revolutionizing aerospace manufacturing and driving the industry forward.

Lightweight Components and Fuel Efficiency

One of the most significant advantages of 3D printing in the aerospace industry is the ability to produce lightweight components without compromising strength. In aerospace, every gram counts, as reducing weight directly translates to improved fuel efficiency and lower operational costs. Traditional manufacturing techniques often require joining multiple parts together, adding extra weight due to fasteners and connectors. 3D printing, however, allows for the creation of complex, monolithic structures that eliminate the need for additional parts and reduce overall weight.

For example, 3D-printed parts can be designed with intricate lattice structures that maintain strength while significantly reducing mass. These lightweight components are particularly valuable in applications such as aircraft engines, where reducing weight can lead to substantial fuel savings over the lifetime of the aircraft. As fuel costs continue to rise, the ability to produce lighter, more efficient components through 3D printing is becoming increasingly important for the aerospace industry.

Complex Geometries and Customization

Aerospace components often require complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. 3D printing offers unparalleled design freedom, enabling engineers to create parts with intricate internal structures, optimized shapes, and integrated functionalities. This capability is particularly valuable in the production of components like turbine blades, fuel nozzles, and air ducts, where precise geometries are crucial for performance.

Moreover, 3D printing allows for the customization of parts to meet specific requirements. For instance, components can be tailored to fit the unique aerodynamic profiles of different aircraft models, improving overall performance and efficiency. This level of customization is also beneficial in the maintenance and repair of older aircraft, where replacement parts may no longer be readily available. 3D printing enables the production of bespoke parts on demand, extending the lifespan of aircraft and reducing downtime.

Reducing Production Lead Times

In the aerospace industry, where production lead times can span several months or even years, the ability to accelerate manufacturing processes is highly valuable. Commercial 3D printing services significantly reduce the time required to produce complex components, allowing for faster prototyping, testing, and production. This speed is particularly beneficial in the development of new aircraft models, where rapid iteration and testing are essential to meeting tight project timelines.

Additionally, 3D printing enables more agile production, allowing manufacturers to quickly respond to changes in demand or design specifications. This flexibility is crucial in an industry where technological advancements and regulatory requirements are constantly evolving. By reducing lead times, 3D printing helps aerospace companies bring new products to market more quickly, maintaining their competitive edge in a fast-paced industry.

Conclusion

Commercial 3D printing services are revolutionizing the aerospace industry by enabling the production of lightweight, complex, and customized components with unprecedented efficiency. By reducing weight, enhancing design flexibility, and accelerating production lead times, 3D printing is helping aerospace manufacturers achieve new levels of performance and innovation. As the technology continues to advance, its role in the aerospace industry is expected to grow, offering even greater opportunities for enhancing efficiency, sustainability, and competitiveness.